The fourth industrial revolution, also known as Industry 4.0, presents manufacturers with changes on multiple fronts. Thorgate has a successful track record of working hand-in-hand with factories, replacing the inefficiencies of traditional automation with innovations brought about by the Internet of Things.

As we move through this exciting time with our clients, we are fully acquainted with the challenges that manufacturers face daily. A team of savvy problem solvers by nature, Thorgate has designed a number of automation solutions, reducing costs and increasing profits for our clients. Many of our clients are now less preoccupied with daily operations and are more available to tackle strategic goals, with the added bonus of increased transparency across all stages of production. Thorgate has already shaped the processes for the likes of Krah Pipes, Pomemet and Vaheladu, streamlining production and complex assembly lines involving multiple vendors.

Krah Pipes — powerful production line optimisation

Krah Pipes are well known for their capacity to produce custom made pipes for various projects, requiring a high level of precision. With manual data collection, production planning, workforce management and quality checks, the processes can work out to be rather resource and time-heavy. That’s where Thorgate comes in.

When working with Krah Pipes, our team focused on two key challenges — production planning and quality control. We modelled a system that enables Krah Pipes to keep the production line working 24/7 and reduce the time that goes into processing orders and conducting manual quality control.

As the orders arrive in the system, the production manager can easily compile a production schedule by breaking down the orders into smaller sections. This list is then used by the line operator who activates the production line. A timestamp of this action is saved, allowing for the consistent assessment of the production schedule, machinery maintenance rates and the productivity of staff. Once the pipe has been produced, a heating sensor alerts the production staff when it is ready to be transferred from the mold to be quality checked. Before embarking on this ambitious project, Krah Pipes employed a quality assurance specialist to visually assess the condition of the pipes. Today, every single pipe is processed by a fully automated measuring bench. A laser image of the pipe is matched with tolerance lines for an immediate quality report. As a result, Krah Pipes now has a full overview of its production line through the use of a single centralised, up-to-date digital production management platform.

Pomemet - boosted staff productivity through production tracking

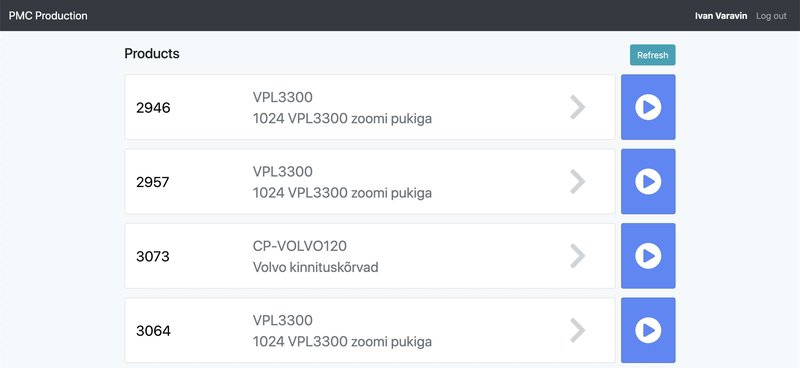

We concentrated even further on employee efficiency in our latest project with Pomemet. Pomemet assembles and customises construction machinery components.

In order to provide their clients with realistic timelines, the managing staff at Pomemet needed to physically monitor and individually track each item as it was being assembled. This presented challenges in setting and tracking a standardised production flow.

Everything changed when Thorgate designed a solution for tracking and measuring the production quality by assigning individual staff profiles that track everything from production time to quality. The results are used to scale the pay of the individual welders against average production time and quality.

The production manager puts into action a schedule for each welder. The welder then records the beginning and end of each project that is automatically associated with the staff profile. Once the product reaches quality control, this detailed, centralised information will allow for seamless troubleshooting.

Vaheladu - increased transparency through all stages of harvest

While Krah Pipes and Pomemet involved the automation of a single manufacturing unit, Vaheladu is an expansive tracking system connecting multiple vendors in the forestry industry. It is the most popular private forest management system and is used by 230 forestry companies in Estonia.

The system tracks the movement of timber from the moment it is harvested all the way to its final destination at the depot. This information is logged by the intelligent tracking devices on board the harvester, forwarder and transport truck. Before the system was implemented, forestry companies had at best a vague understanding of the capacity of the timber stock ready for collection. Therefore, any losses would have been hard if not impossible to monitor. As with Vaheladu, companies have a complete picture of how much timber is located in the forest, stored at the clearing and picked up by the transport truck.

Manufacturers must decide where and how to invest in new technologies. Thorgate, with its vast portfolio of production planning projects, helps companies identify which ones will drive the most benefit to the client’s organisation. Automation is a constant process, and we continuously work side-by-side with our clients to not only meet, but exceed their business objectives.